What is Jacqform™?

Utilizing Studio Z's Jacqform™ utility patent, designer Anna Zaharakos develops woven fabric parts that enhance design and simplify the manufacturing process of products that utilize textiles. Instead of viewing fabric at the end of the product design process or as just an applied surface, Anna integrates woven design within a products specific goals and geometry. The result is a jacquard woven textile with laser or scissor cut textile components. These components are then ready for manipulation and application. Jacqform™ creates product-tailored components with strong woven in seams, part-specific registered patterns, woven-in pockets, channels, extensions, and other details in a consistent repeatable process. Jacqform™ allows for capabilities and forms that are not achievable with sewing. This ground-breaking technology minimizes waste, sewing, and hand work, while maximizing strength and customization. It is a dynamic and fresh look at the end product and textile relationship.

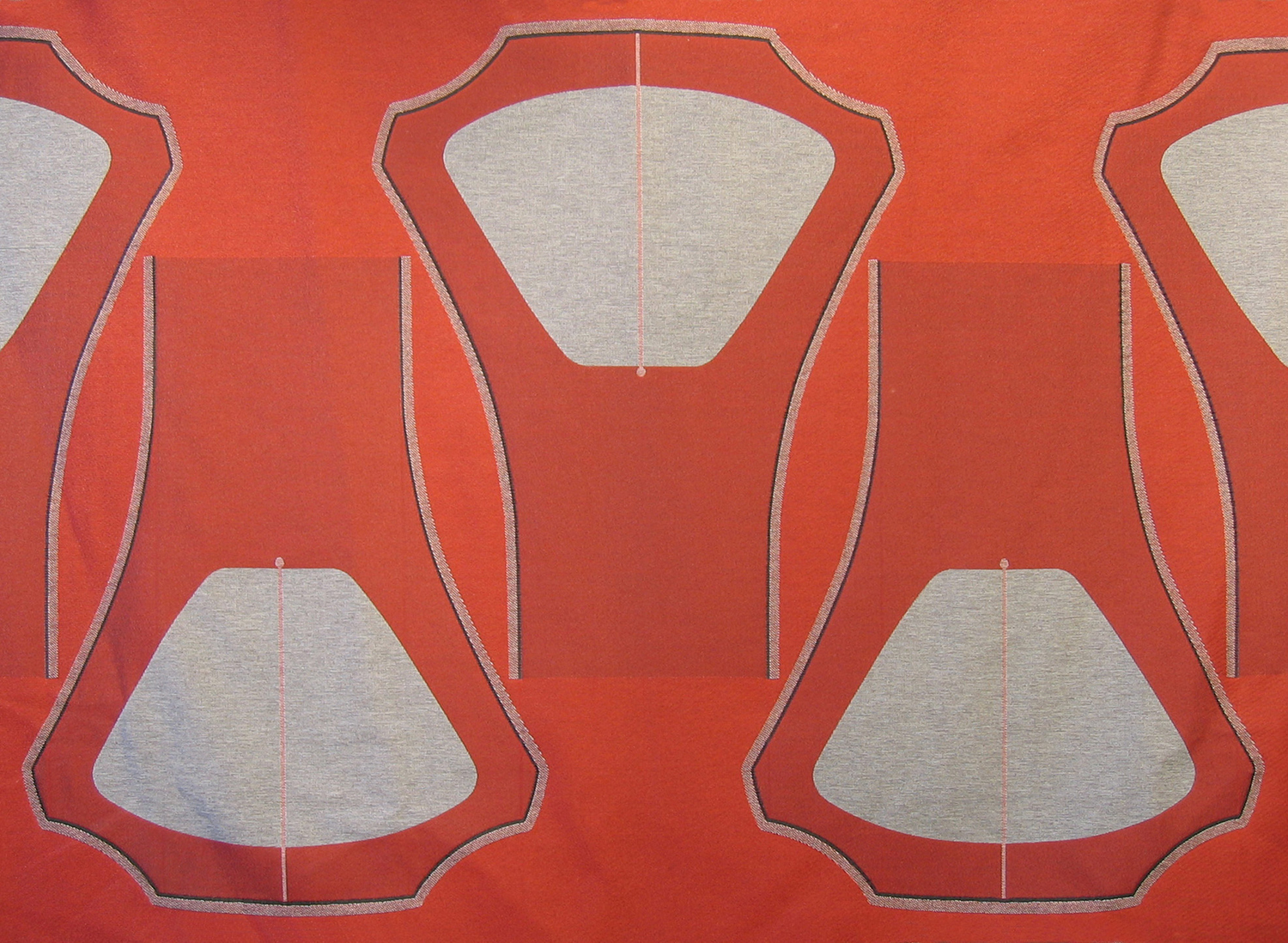

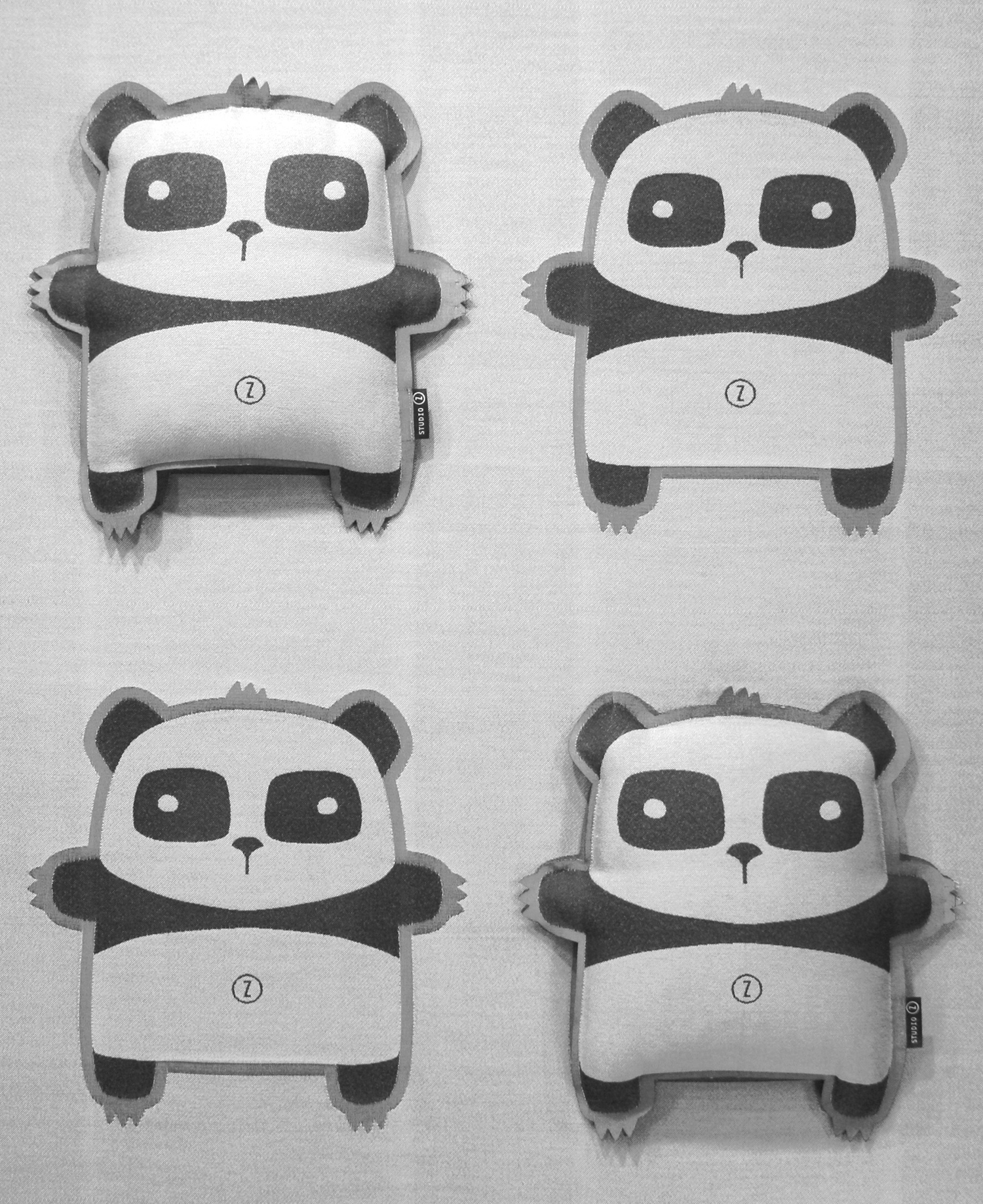

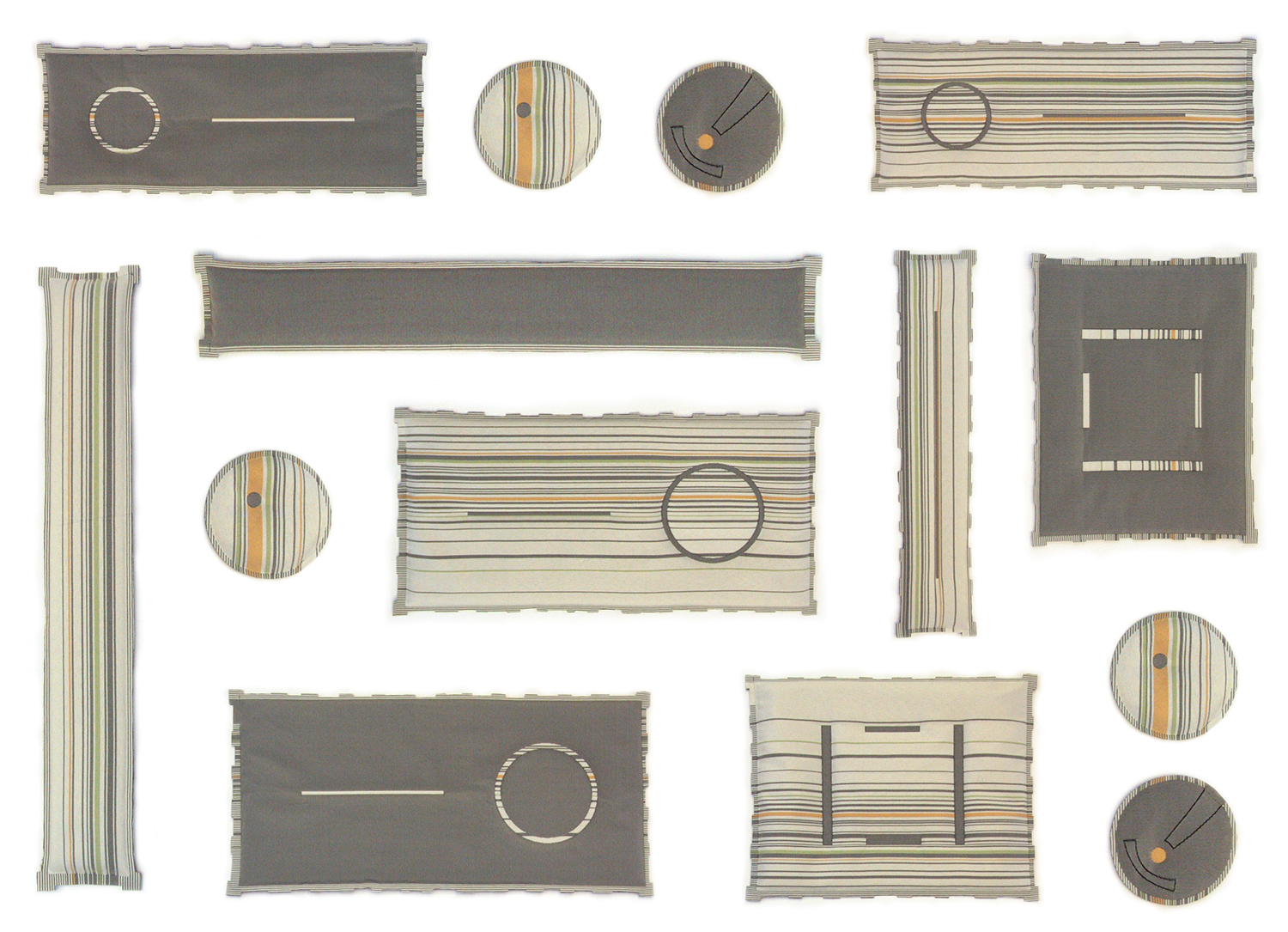

Integration and Coordination.

Jacqform™ parts can be tailored and tightly integrated into furniture. Shown here with the Audrey seating line for Izzy.

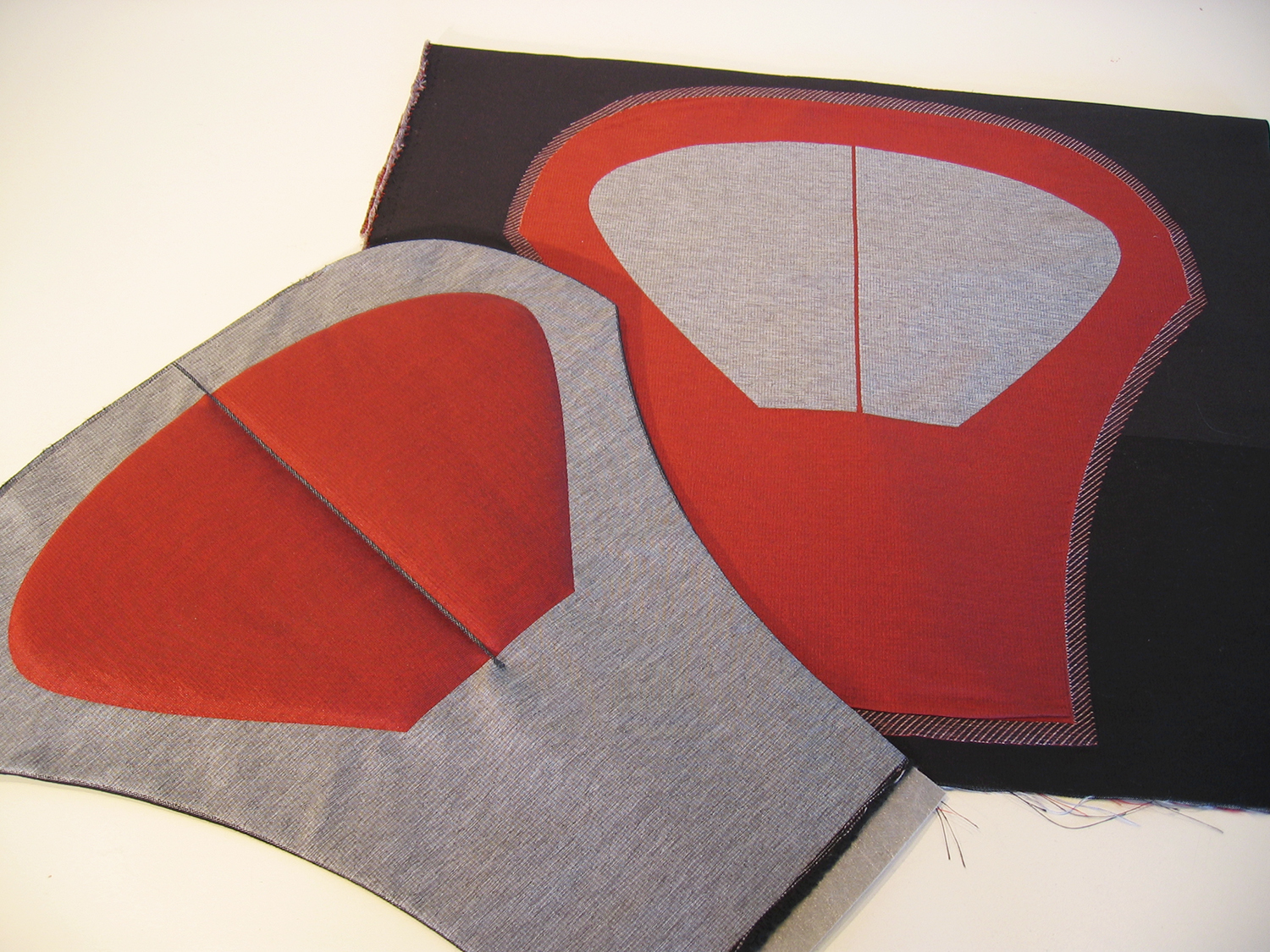

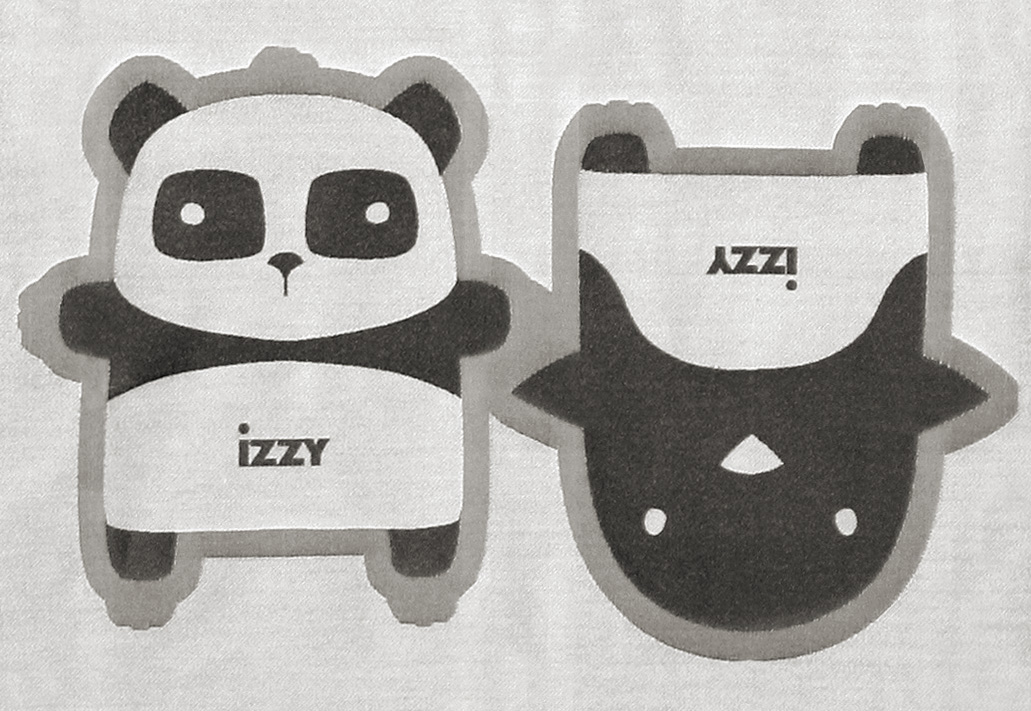

Customization.

Utilizing the 200 year old technology of Jacquard weaving, we create products with woven-in seams, details, custom graphics, and pockets.

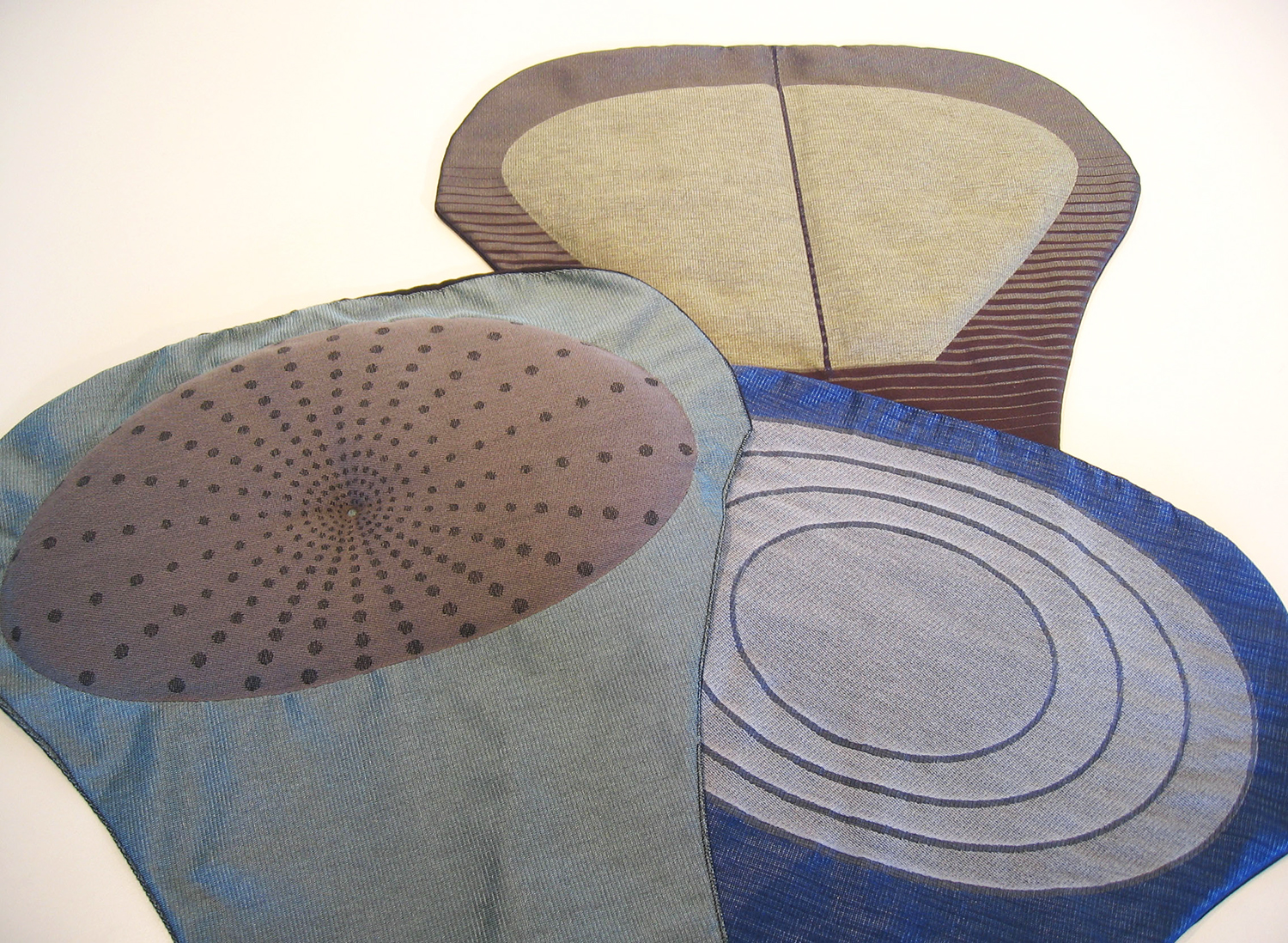

Innovative Graphic Application.

Jacqform™ parts can be turned inside-out for a traditional seam look, with perfectly registered image wrapping.

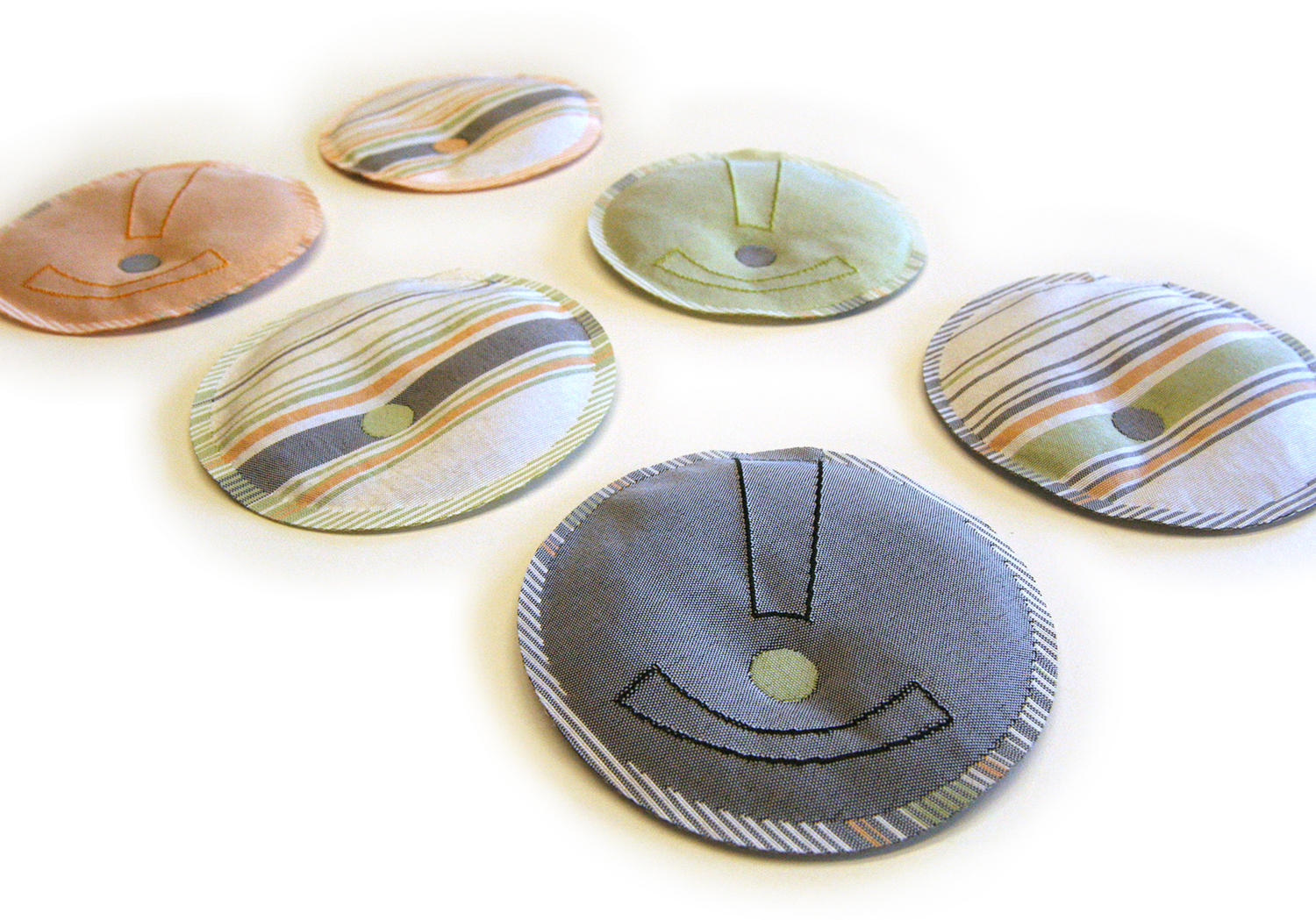

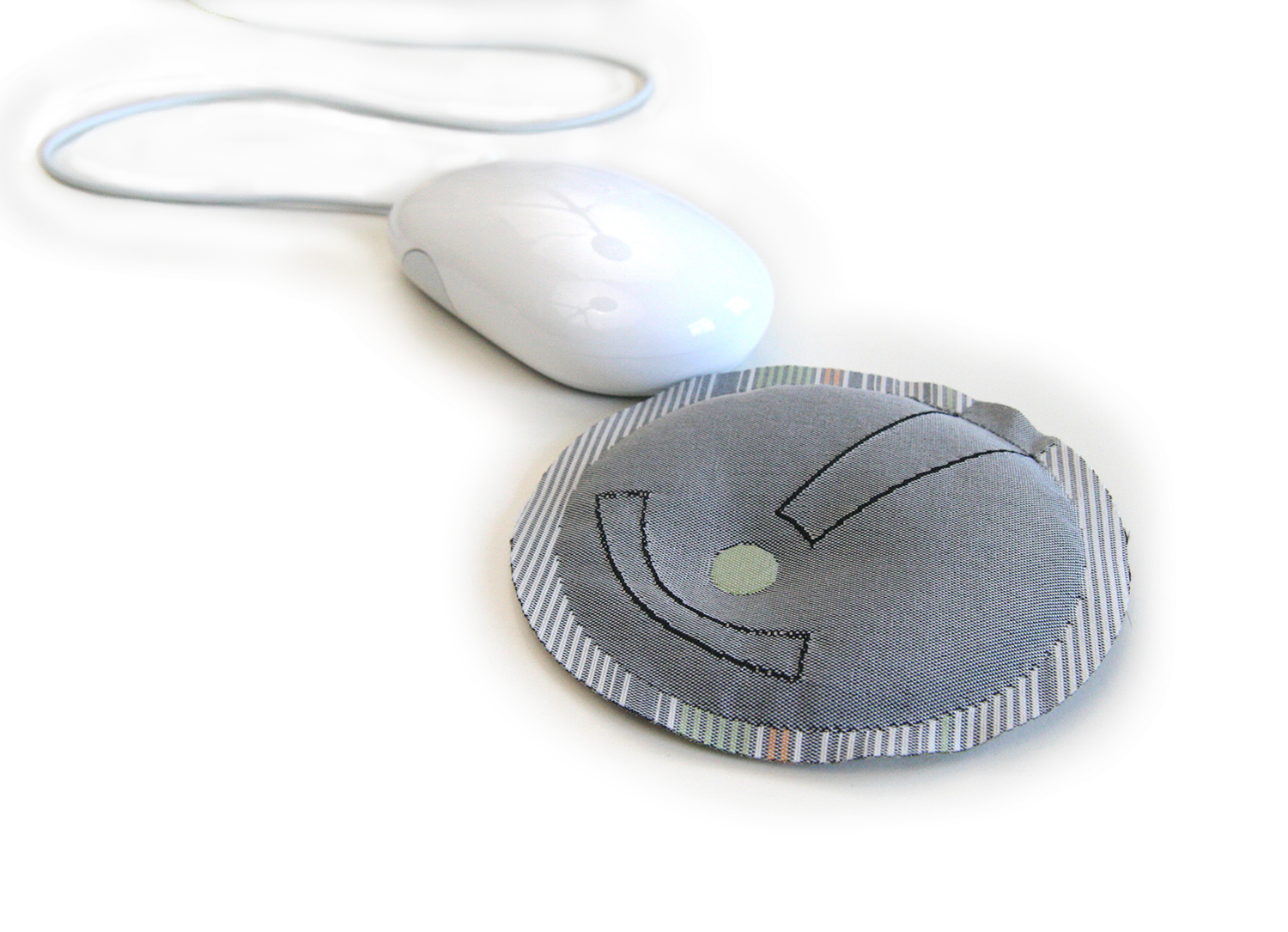

Unique Aesthetic and Function.

Jacqform™ plus laser cutting equals aesthetic freedom. The woven-in borders binding the two layers are cut to add unique functionality and shape.

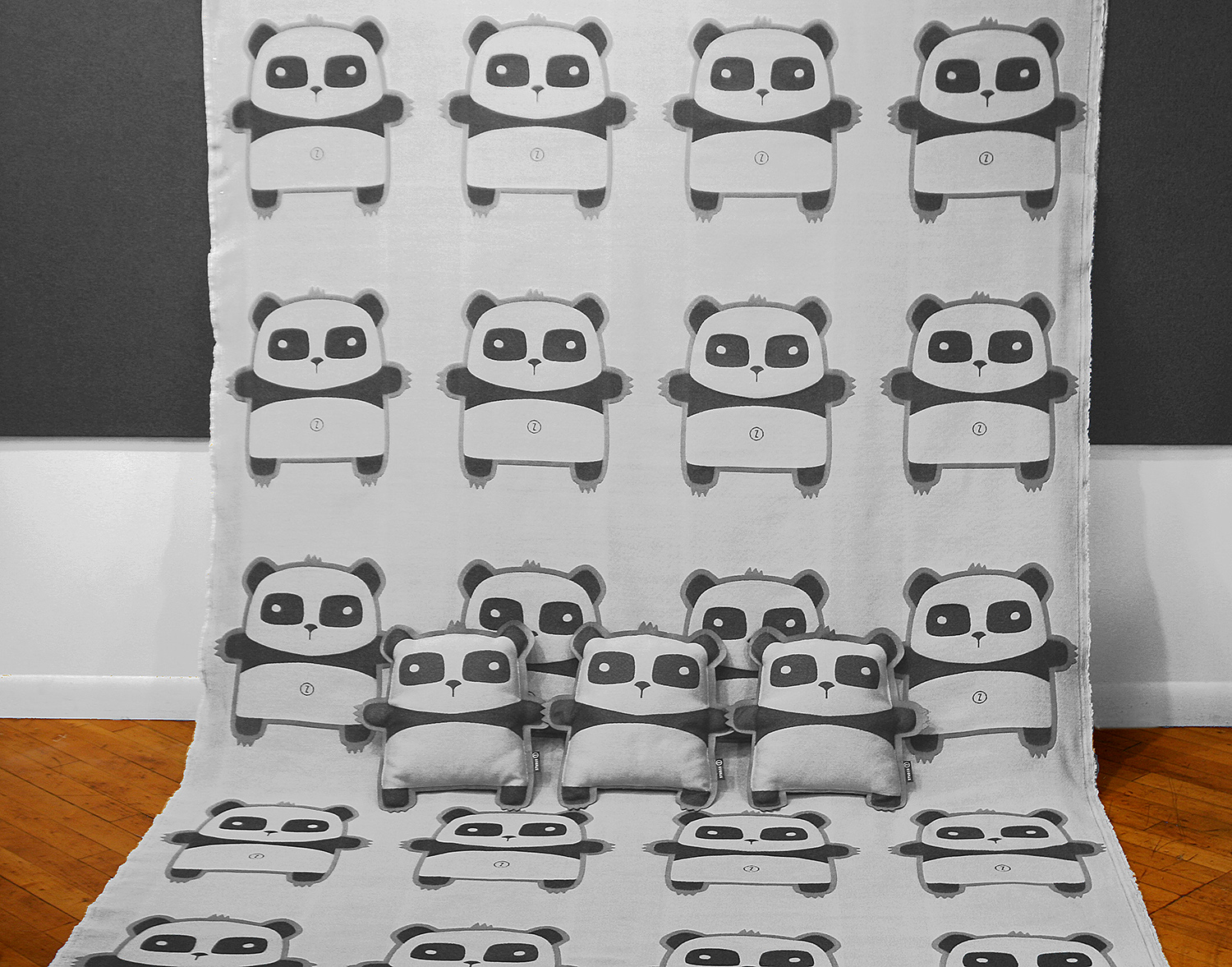

The Whole Part.

Jacqform™ parts can be the full loom width and theoretically infinite in length, allowing for complete and custom parts.